Soderberg Electrodes Paste

Soderberg Electrode Paste is produced from calcined petroleum coke (or calcined pitch coke, Electrically Calcined Anthracite Coal), calcined anthracite, coal tar pitch and other additional materials. It is used as conductor in submerged arc furnace under self-baking process while manufacturing different types of Ferro Alloys and Calcium Carbides.

- Product Details

Soderberg Electrode Paste is also called Anode Paste, Self-baking Electrodes Paste or Electrode Carbon Paste. It is produced from calcined petroleum coke (or calcined pitch coke, Electrically Calcined Anthracite Coal), calcined anthracite, coal tar pitch and other additional materials. It is used as conductor in submerged arc furnace under self-baking process while manufacturing different types of Ferro Alloys and Calcium Carbides.

Soderberg Electrode Paste is fed into smelting furnaces column in different forms: cylinders, eggs, briquettes and polygonal blocks. Blocks and cylinders are moulded into pieces in medium to large dimensions related with different electrode sizes.

Electrode Paste Briquettes: 60x80x100 mm

Electrode Paste eggs: 50x100mm

Electrode Paste Cylinders: Ø500, Ø600, Ø700, Ø800, Ø900, Ø1000

Packing:

1). briquettes are loaded in bulk or packed in big-bags

2). cylinders are steel strapped on wooden pallets and can be covered with plastic foil

Properties:

1). Low Electrical Resistivity

2). High Mechanical Strength

3). Low Porosity

Technical specification:

Type

CP-1

CP-2

CP-3

CP-4

CP-5

Ash content % (max)

4,0

6,0

7,0

9,0

11,0

Volatiles content %

12,0-15,5

12,0-15,5

9,5-13,5

11,5-15,5

11,5-15,5

Bulk density g/cm3 (min)

1,38

1,38

1,38

1,38

1,38

Compressive strength MPa (min)

18

17

22

21

20

Resistivity µΩ·m (max)

65

75

80

85

90

Elongation %

5-20

5-20

5-30

15-40

15-40

If required, other values of parameters might be agreed upon.

The waterproof graphite for process equipment is manufactured in two main steps at Orient Carbon Industry Co., Ltd. First, synthetic graphite is made. Then this material is impregnated with phenolic resin to make it waterproof and improve the mechanical characteristics.

Orient Carbon Industry Co., Ltd uses exclusively graphite of higher quality. Our process uses a fine grain, homogeneous graphite, with a compact grain structure, an optimal distribution of grain and pore sizes and free of structural irregularities such as cracks, large pores or impurities.

Orient Carbon Industry Co., Ltd has developed, in close collaboration with a renowned European resin manufacturer, a phenolic resin that is optimized for the type of graphite it uses in its manufacturing processes.

Manufacturing Process of Synthetic Graphite

The manufacturing process of synthetic graphite includes numerous steps: powder preparation, shape moulding, baking, impregnation or densification of the coating, re-baking and finally, graphitization.

Market Advantages of Orient Carbon Industry Co., Ltd Product

- As we have the technique and production process above, our products have excellent quality

- As the production is close to the place of production of the raw materials, we can efficiently reduce the cost of production, for that reason, we have an evident cost advantage

- As in the application of the product of the electrode paste there is a comparatively high technical requirement, that's why the service is an important aspect that presents the competitive corporate strategy, for that, our company installed the special and professional after-sales service group, always is prepared to provide efficient support for customers.

Related Products

Pre-baked Anode Block

Anodes are large carbon blocks which are used to conduct electricity during the aluminium...

Pre-baked Anode Block

Anodes are large carbon blocks which are used to conduct electricity during the aluminium...

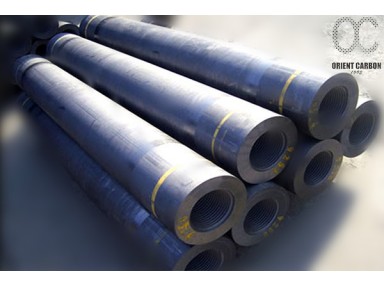

HP Graphite Electrode

Physical & Chemical Properties of HP Graphite Electrodes ...

HP Graphite Electrode

Physical & Chemical Properties of HP Graphite Electrodes ...

RP Graphite Electrode

Physical & Chemical Properties of RP Graphite Electrodes...

RP Graphite Electrode

Physical & Chemical Properties of RP Graphite Electrodes...