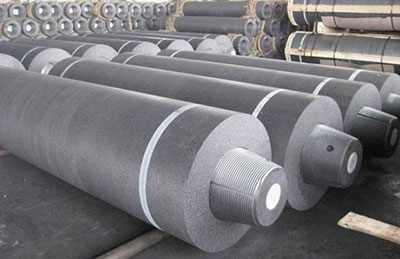

High resistance of graphite electrode nipples is one of the main reasons for the quality problems in steel-making. During the process of steel-making in EAF, if the resistance value at the connection between electrode body and nipple is high, the electric conductivity of this part will be reduced. And it will lead to arcing, burning, shedding and even breaking of graphite electrode. Meanwhile, the consumption of

graphite electrode will increase in steel-making. The situation will have a great impact on the normal production of steel-making furnace.

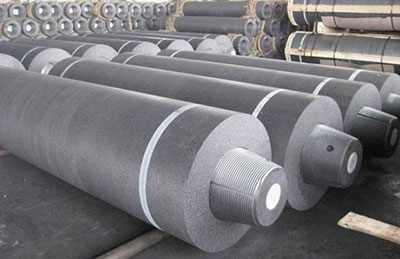

As an important physical performance index of carbon products and their raw materials, the measurement of graphite electrode resistance is of great significance to guide the production and application of graphite electrode. As the resistance of the electrode body is one of the most basic parameters in the design of the measuring device, calculating the electrode resistance is necessary to determine the power supply capacity in the design of the measuring device.

In order to facilitate the analysis and calculation, the resistance of the

graphite electrode can be regarded as the sum of a series resistance. Generally, the measuring device includes mechanical transportation and transmission mechanism, rectifier and instrument. The basic principles of its design are as follows:

1. high measurement accuracy and good repetitiveness.

2. high level of automation and simple operation method.

Prev: What are the advantages of EDM graphite electrode?

Next: Development of graphite deep processing technology