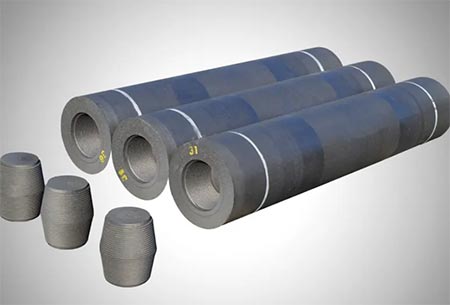

What are the grade graphite electrodes?

1. Regular Power (RP) Graphite Electrodes:

Usage: Suitable for use in regular power arc furnaces that operate at lower current densities.Characteristics: These electrodes have a relatively lower density and mechanical strength. They are typically used in environments where the demands on the electrode are not as intense.

2. High Power (HP) Graphite Electrodes:

Usage: Designed for high-power arc furnaces that operate at higher current densities than regular power furnaces.Characteristics: They possess higher density and mechanical strength compared to RP electrodes, allowing them to handle higher electrical currents and more intense thermal and mechanical stress.

3. Ultra-High Power (UHP) Graphite Electrodes:

Usage: Intended for ultra-high power arc furnaces that operate at very high current densities.Characteristics: These electrodes have the highest density and mechanical strength among the three grades. They are capable of withstanding the most extreme conditions in steel production, including very high temperatures and electrical currents. UHP electrodes are essential for producing high-quality steel efficiently and effectively.

Factors Differentiating Graphite Electrode Grades

Thermal and Mechanical Stress Resistance: UHP electrodes are designed to endure the highest levels of thermal and mechanical stress.

Purity and Quality: Higher grades of electrodes have better purity levels, which helps in reducing contamination in the steel produced.

Applications and Selection Criteria

In summary, the grade of graphite electrodes is a key factor in their performance and suitability for different types of steelmaking operations, with each grade offering unique properties tailored to specific industrial needs.