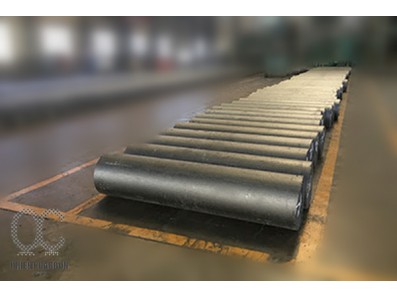

UHP Graphite Electrode

The production process for UHP grade:

Needle coke and pitch are mixed and then molded. Heat treatment is then applied in the baking and graphitization process to form the finished product.

- Product Details

Physical & Chemical Properties of UHP Graphite Electrodes

|

Items |

Classification |

Unit |

Nominal Diameter (mm) |

|||

|

250-400 |

450-500 |

550-650 |

700-800 |

|||

|

Resistivity |

Electrode |

μΩm ≤ |

6.2 |

6.3 |

6.0 |

5.8 |

|

Nipple |

5.3 |

5.3 |

4.5 |

4.3 |

||

|

Bending Strength |

Electrode |

Mpa ≥ |

10.5 |

10.5 |

10.0 |

10.0 |

|

Nipple |

20.0 |

20.0 |

22.0 |

23.0 |

||

|

Young’s Modulus |

Electrode |

Gpa ≤ |

14.0 |

14.0 |

14.0 |

14.0 |

|

Nipple |

20.0 |

20.0 |

22.0 |

22.0 |

||

|

Bulk Density |

Electrode |

g/cm3 ≥ |

1.67 |

1.66 |

1.66 |

1.68 |

|

Nipple |

1.74 |

1.75 |

1.78 |

1.78 |

||

|

CTE(100℃-600℃) |

Electrode |

×10-6/℃ ≤ |

1.5 |

1.5 |

1.5 |

1.5 |

|

Nipple |

1.4 |

1.4 |

1.3 |

1.3 |

||

|

Ash Content |

Electrode |

% ≤ |

0.5 |

0.5 |

0.5 |

0.5 |

|

Nipple |

||||||

Note: Ash Content is only for reference.

Recommended current load of UHP Graphite Electrodes

Grade

Nominal Dia.

Allowable current A

Current density A/cm2

UHP electrode

AC

DC

AC

DC

300mm

15000~22000

20~30

350mm

20000~30000

-

20~30

-

400mm

25000~40000

-

19~30

-

450mm

32000~45000

-

19~27

-

500mm

38000~55000

-

18~27

-

550mm

45000~65000

49000~78000

18~27

20~32

600mm

50000~75000

58000~93000

18~26

20~32

650mm

60000~85000

60000~110000

18~25

20~30

700mm

70000~120000

79000~130000

18~30

20~30

Related Products

Soderberg Electrodes Paste

Soderberg Electrode Paste is also called Anode Paste, Self-baking Electrodes Paste or Electrode...

Soderberg Electrodes Paste

Soderberg Electrode Paste is also called Anode Paste, Self-baking Electrodes Paste or Electrode...

Pre-baked Anode Block

Anodes are large carbon blocks which are used to conduct electricity during the aluminium...

Pre-baked Anode Block

Anodes are large carbon blocks which are used to conduct electricity during the aluminium...

Graphite Electrode

Graphite Electrode Soldering Iron

Graphite electrode is nothing more than a sharp...

Graphite Electrode

Graphite Electrode Soldering Iron

Graphite electrode is nothing more than a sharp...