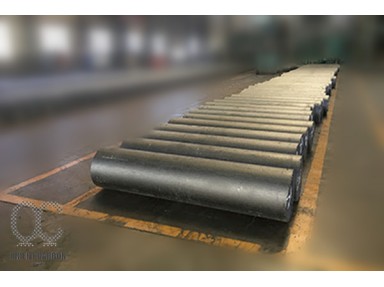

Carbon Electrode

Carbon electrode are applied for the production of silicon metal as they have peculiar characteristics. Carbon electrode are used as electric current conductors in electric furnaces where silicon metal, elemental phosphorus or -to a small extent -other specialties are produced.

- Product Details

Carbon electrode are applied for the production of silicon metal as they have peculiar characteristics.

Carbon electrode is used as electric current conductors in electric furnaces where silicon metal, elemental phosphorus or -to a small extent -other specialties are produced.

Requirements for carbon electrode are:

- Good electrical conductivity: in order to withstand the high current density required by the metallurgical process.

- Good thermal conductivity: to minimize the temperature differences inside the electrodes when in use and, consequently to reduce internal stresses.

- Good mechanical strength: to withstand the stresses when in use.

- High level of chemical purity: to avoid polluting the end product.

- Reliable joint: to ensure current flow continuity in the electrode column.

- Easy mounting: to facilitate and speed up operations for the lengthening of the electrode column.

- Accurate machining on the external surface on the joints: to avoid problems when the joint passes through the holding clamps and the contact shoes and to facilitate the current flow from one electrode to the following one.

Peculiar characteristics of carbon electrodes for silicon metal production are:

- Carry large amounts of electrical current.

- Withstand very high temperatures.

- Keeping good mechanical properties under above-described circumstances.

What are the benefits of using the carbon electrode?

Day by day there exist so many industries that move

started to use the carbon electrode because it

remains the most utilized in several kinds of machinery. Once you realize the

worth of it surely you will never choose another one at any time. Still, there

is nothing can replace the worth of it because it is the most wanted one for

all the people.

Highly preferred one forever

It implies essentially utilized for the electrolysis

method plus it remains to have a high melting point also. If you are having any

doubt to use it you will clarify it from the internet. Now it is available at a

very low cost also that is the main reason for it becomes the stunning one than

the other. It is available in two for which denotes insert electrodes including

active electrodes.

It holds the widely utilized one for many types of machinery. Hereafter you no need to worry about where you can get better results about to choose the carbon electrode. Now you will have a clear idea about it so try to share the merits of it with everyone. You can also suggest who needs it plus it will be more helpful for them.

|

Type |

S grade |

G grade |

|

Bulk density g/cm3 (min) |

1,58 |

1,58 |

|

Resistivity µΩ·m (max) |

35 |

30 |

|

Ash content % (max) |

4,5 |

4,0 |

|

Compressive strength MPa (min) |

6,5 |

6,5 |

|

CTE 10-6/℃ (max) |

4,5 |

4,0 |

Diameter mm

Nominal Length

Standard Length

Short Length

max

min

max

min

Φ700/Φ780/Φ800/Φ850

1950

+50

-50

-50

-200

Φ870/Φ900/Φ920/Φ960

1950

+50

-50

-50

-225

Φ960/Φ1020/Φ1060/Φ1140

2550

+100

-100

-100

-275

Φ1060/Φ1140/Φ1272

2850

+100

-100

-100

-275

Diameter (mm)

S-Grade Carbon Electrode

G-Grade Carbon Electrode

Allowable Current Load (A)

Current Density

Allowable Current Load (A)

Current Density

700

25300

6.6

29200

7.6

780

32500

6.6

36200

7.6

800

33100

6.6

38100

7.6

850

36200

6.6

41900

7.4

870

38000

6.4

43900

7.4

900

40600

6.4

47000

7.4

920

42500

6.4

49100

7.4

960

46300

6.4

53500

7.4

1020

50600

6.2

57900

7.1

1060

54600

6.2

62600

7.1

1140

62200

6.1

71400

7.0

1146

62800

6.1

72100

7.0

2405

66100

5.8

76300

6.7

1272

73600

5.8

85100

6.7

1321

73900

5.4

84900

6.2

1400

80000

5.2

92300

6.0

(A/CM2)

(A/CM2)

If required, other values of parameters might be agreed upon.

Related Products

UHP Graphite Electrode

Physical & Chemical Properties of UHP Graphite Electrodes...

UHP Graphite Electrode

Physical & Chemical Properties of UHP Graphite Electrodes...

HP Graphite Electrode

Physical & Chemical Properties of HP Graphite Electrodes ...

HP Graphite Electrode

Physical & Chemical Properties of HP Graphite Electrodes ...

Cathode Block

Cathode blocks are critical materials for production of primary aluminium. The blocks must...

Cathode Block

Cathode blocks are critical materials for production of primary aluminium. The blocks must...